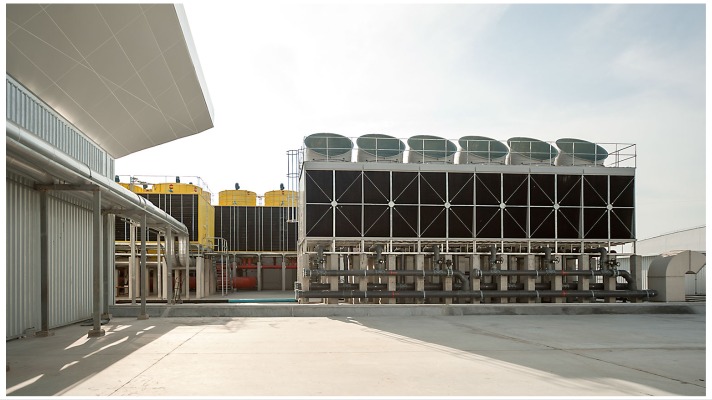

Overview

Cooling towers are potent heat exchangers for a range of industrial processes which regulate temperature. If you find some issue with your cooling tower system, then you have to visit a company that provides good and quality cooling tower service for your system. If installation quality is supreme, then you will not experience such a maintenance problem. The cooling tower’s consistency affects operating performance, operating costs, equipment expense, and the reliability of the cooling system. Longevity depends upon maintenance even when quality machinery and equipment are built. You have to take care of the cooling tower from an experienced company even though you have it built. We at Jateen Trading Co. offer the best and top-notch services for our customer’s cooling tower system.

Here, we need to consider a few factors in order to keep your cooling system efficient. We need to do periodical inspection or routine check. The experts must carry out the repair and maintenance. This would not only boost the life of the system but also minimize costs and avoid significant problems in the system. This is the only way to reduce considerable maintenance costs.

What are the cooling tower treatment problems, and how to solve them?

High amount of blowdown:

Since cooling towers extract heat by the evaporation process, it is no wonder that they can, in turn, make the difference using a lot of water. Large quantities of solids will remain after evaporation, depending on the quality of makeup water added to the cooling tower and the device’s operating efficiency. This can contribute to an increased in need to “blow down” or remove solid waste and dissolved material from the flowing water before equipment can be scale or corrode.

Blowdown also contributes to water movement and chemicals and solid wastes, so it’s essential to keep a close eye on it. If you want too much blowdown in your cooling tower, the water treatment system can not operate as effectively as it should. An efficient water treatment system for the cooling tower would maintain a controllable blowdown. In turn, this helps to retain the quantity of any water or chemical composite material required and resulting in greater solid waste.

How to solve this issue:

Consult a cooling tower water management specialist if you need higher than usual blowdowns. Depending on the causes of the problem, some solutions to reduce cold tower blowdown can include:

- Enhanced water filtration feed.

- Filtration with high-quality side stream.

- An increased cycle of concentration.

- You need to maintain improved makeup water chemistry by eliminating impurities causing the formation and corrosion of the scale.

- Change or control the feed chemistry program for the cooling tower closely.

A low cycle of concentration:

In cooling towers, the cycle of concentration is a ratio of condensed solids to measuring the conductivity in blower water in the cooling tower process water. A facility should have a concentration interval of at least three to six cycles of concentration. The higher your concentration cycle, the less water and blowdown you need to make up and save water, toxic substances, and costs. Water consumption and chemical consumption can be substantially high for systems operating at low concentration cycles, contributing to over cost.

How can you solve them?

The best solution is to visit the best cooling tower service, expert. However, several ways to improve your focus cycles will usually include:

- Better tower management by minimizing the conductivity of blowdown monitoring.

- Regulation of pH/alkalinity to reduce the formation size.

- Reduce the hardness of feed, iron, and silica.

- Microbial growth control.

Not accounting for secondary waste treatment:

Any discharge produced by your device must fulfill all local regulatory requirements. Feedwater contaminants affect secondary waste volume and processing requirements. We also need to process and discharge these secondary waste.

How to solve them?

You can get a copy of the permit specifications, study them carefully and plan your secondary treatment and downtime procedures. This will therefore fulfill the effluent release. This ensures that the plant meets or discharges the effluent targets.

Water scarcity/ supply:

These water scarcity facilities are already being faced, and hence, local restrictions on how much water you can collect and release will become tighter. You may have higher sewage link fees if your facility draws your water from or drains into a municipal source. If a cooling tower works ineffectively, there may be a surplus of makeup water and an unnecessary blowdown. Also, if your waste is returned to the area, the disposal of your cooling tower bleed would comply with the local municipal discharge law. So, in order to avoid being fined, it’s necessary to fix these problems directly.

How can you solve this?

Few more problems of cooling tower:

There are various problems that can occur during the cooling tower treatment process for companies that use cooling towers to eliminate heating from a manufacturing process or cool large buildings.

Since these problems always arise, it is useful to know what you should look for to save your time and money. Besides the problems mentioned above, the following can also cause:

- Corrosion: In cooling systems, corrosion is very common. Many industries, particularly in old cooling towers, accept corrosion as an unavoidable process. We keep cooling towers in open place, and thus, causing environmental effects by corrosion in the cooling tower. This problem becomes worse as the water’s pH levels become more unstable.

- Scaling: Calcium phosphate, calcium carbonate, magnesium silicate, and silica in the water are insoluble in heated water. The insoluble compounds cause hard deposits to form on the heat exchange surface of the system. These developments are scaling. They damage the piping and inner cooling system surface.

- Fouling: If unnecessary materials are present in the cooling towers, then it is fouling. Fouling of the cooling systems is not only the result of the formation of dust, dirt, and derbies, but it also includes other materials such as slitting, microbiological growth, migratory corrosion products, sand, etc.

- Foaming: While not as frequent as the other principal causes of problems in cooling towers, the cascade of water in the tower can produce foaming. The cooling tower will either overflow, or the fans can blast moisture from the top of the tower.

Bottom Line

In this blog, we have mention some problems that can happen to your cooling tower system if appropriate service or maintenance is not done. We at Jateen Trading Co. here offer many services to your cooling tower as per data and requirement of your system. Check out our website to see our services and chemicals we provide. If you have any queries regarding the cooling tower system or its maintenance, then without any hassle, please do contact us! If you find this blog engaging, then please check out our blog page too.